Robotic Production Process

At the new corporate headquarters and manufacturing facilities Helioakmi S.A Solar Energy Systems Manufacturer produces high standard solar water heaters.

Our Group of companies includes 2 production units:

a. HELIOAKMI S.A. – Solar Water Heaters, Solar Panels, Forced Circulation Systems

b. ASSOS BOILERS (SOLARNET S.A.) – Boilers, Solar Heaters, Forced Circulation Systems

Helioakmi S.A. Solar Energy Systems Manufacturer is one of the oldest companies exclusively involved in the research and development of solar energy systems with products distributed worldwide for many years with great success.

Thousands of hot water solar heaters and solar panels have been installed at homes, hotels, hospitals, swimming pools, green-houses, factories, military bases, public and private organizations, etc. offering abundant hot water and assisting in the protection of the environment.

From extensive research & design to the final product

The MEGASUN solar water heaters and solar panels by Helioakmi S.A. are manufactured under the strictest international specifications and their production is inspected at each production stage.

Each MEGASUN solar heater has a special quality and inspection identification badge that certifies:

-

Its quality

-

Its performance

-

Its design

ROBOTIC PRODUCTION PROCESS

1. VIEW OF OUR CONFERENCE ROOM

2. DESIGN OF PRODUCTS AND MOULDS

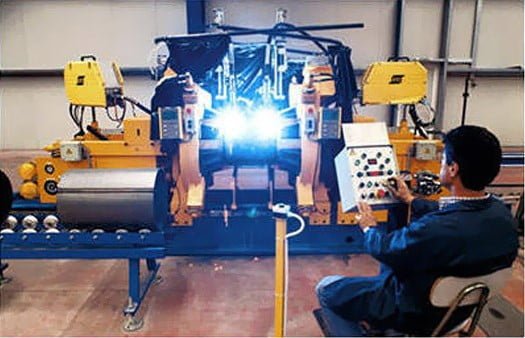

3. AUTOMATIC WELDING MACHINE OF THE STORAGE TANK

4. AUTOMATIC WELDING MACHINE OF THE STORAGE TANK SIDE COVERS

5. PRESSURE TESTING MACHINE

6. AUTOMATIC 6 PHASE METAL BLASTING MACHINE

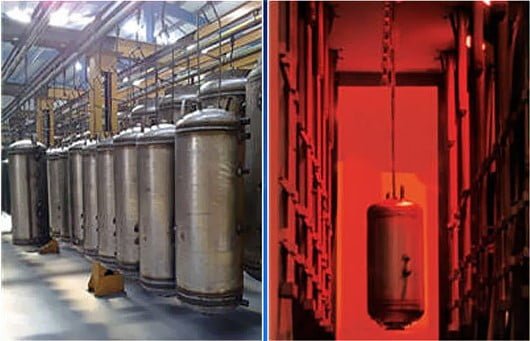

7. AERIAL SUSPENDED PRODUCTION LINES FOR SECURITY AND PROTECTION OF THE ENAMEL

8. DRYING AND POLYMERISATION FURNACE FOR THE INTERNAL PROTECTION OF THE STORAGE TANKS

9. ASSEMBLY OF THE STORAGE TANKS

10. ASSEMBLY AND PACKAGING OF THE COLLECTORS

11. PACKAGING OF THE STORAGE TANKS

CERTIFICATES

HELIOAKMI products (MEGASUN) have been certified by the largest recognized Technology Institutes in the world, such as: Greece, European Union, Germany, France, Italy, Spain, Portugal, Netherlands, Switzerland, Czech Republic, Slovenia, Australia, Korea, Algeria, Botswana, etc.