Forced Circulation Systems

Forced Circulation Solar Systems

MEGASUN Forced Circulation Solar Heating Systems

Ensure maximum performance with minimum cost with our high-standard forced circulation systems.

Why should we use a Solar Water Heating System?

A solar heating system is ecologically friendly. It is economical, simple to install, tasteful, effective and autonomous:

- Ecologically friendly: with a forced circulation system Megasun 500 ltr. with 3 panel ST 2500 of 2.62 m2 /each system, the emissions of C02 avoided annually are equivalent to the fuel emissions of a car having run for 10.000 km

- Economical: will decrease your cost for energy by 70 -100% because the burnerand electric resistance will not need to operate for at least 7-12 months of the year, depends on the sun radiation of each area and the size of the system.

- Simple: The well-studied selection of materials of MEGASUN make. Its Installation safe and easy, reducing the time needed for its installation to a minimum.

- Tasteful: The excellent exterior design of the MEGASUN collectors in combination with their well-studied support base, offer the possibility of a tangent Installation on tiled roofs matching aesthetically with every architectural building design.

- Effective and Autonomous: You have hot water at will 7-12 months per year. During winter time you secure the pre-heating of the water, and the extra hot water needed is secured from conventional energy.

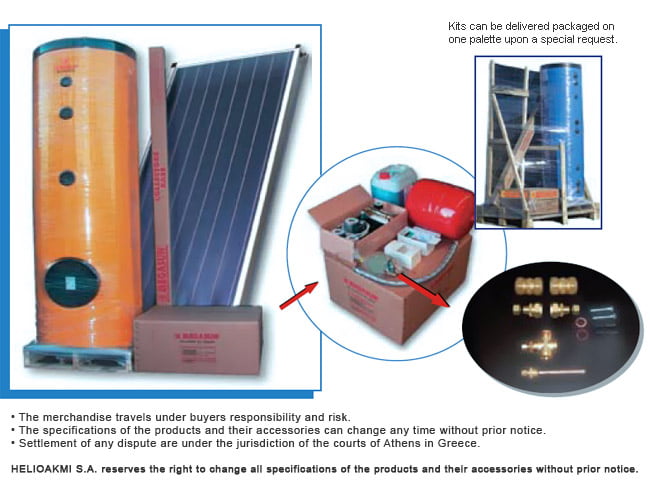

The forced circulation system MEGASUN consists of the following components:

- Boiler with one tube heat exchanger (type BL1) or with two tube heat exchangers (type BL2) on a wooden palette and wrapped with stretch film.

- One (1), Two (2), or Three (3) collectors which are protected during their transport with 4 plastic elbows of hard plastic.

- Accessories (except pipes and wires), the hydraulic kit, expansion pot, differential thermostat, antifreeze liquid and various connection accessories.

- Cardboard box with the metal plates of the support base, the screws, moly plugs, the bolts etc.

Flat Plate Solar Collector Models ST-2000 & ST-2500 SELECTIVES (Titanium)

Description

Flat plate solar collector, firmly built, of new technology suitable for all forced circulation solar systems. The production process and the raw materials that are used produce a high thermal energy efficiency even during periods with insufficient radiation.

Models

The MEGASUN solar collectors are produced in two sizes.The model ST-2000 (2,10 m2) and ST-2500 (2,61m2), with blue titanium selective coating, which can be used either in solo or in combinations to cover all of the requirements of solar systems.

Basic Technical Characteristics

Frame made from anodized aluminum, which is extremely durable to adverse climatic conditions (high humidity – coastal areas).

Strong side and back insulation (20mm glass wool and 35mm rock wool), minimize thermal losses in areas with low seasonal temperatures.

Special prismatic glass, resistant to hale (solar tempered glass).

Absorber made from aluminium treated with a high selective titanium coating. The selective titanium coating is ideal for regions with high diffused radiation and low temperatures, absorbing up to 16% more solar radiation in winter months compared to simple black chrome absorbers. This method of coating is non toxic and does not pollute the environment, while keeping stable its mechanical and optical properties during high and low temperatures.

Dimensions of Flat Plate Solar Collectors

| ST-2000 | ST-2500 | |

| Dimensions | 2050 x 1010 x 90 | 2050 x 1275 x 90 |

| Gross Surface (m2) | 2.10 | 2.61 |

| Capacity (L) | 1.67 | 2.09 |

| Test Pressure (bar) | 10 | 10 |

| Max. Working Pressure (bar) | 7 | 7 |

Flat Plate Solar Collector Models ST-2000 & ST-2500 SELECTIVES (Titanium)

Technical Characteristics

Absorber: a unique sheet of aluminium

Thermal loss: 5%

Total thermal efficiency: 95% ± 2%

Total thermal losses: 5% ± 3%

Absorber a: 95%±2%

Absorber e: 5%±3%

Coating: selective titanium

Diameter of the horizontal tubes: (∅22mm)

Diameter of the vertical tubes: (∅10mm or ∅8mm)

Material: copper

Test Pressure: 10 bars

Maximum functional pressure: 7 bars

Material: heavy aluminum profile

Back insulation: 35 mm insulation

Side insulation: 20 mm glasswool

Material: solar tempered glass

Thickness: 4mm

Watertightness: joint EPDM and transparent silicone

Antifreeze: glicol appropriate for solar systems

Cost-effective, durable boilers ideal for home and professional use made by quality, eco-friendly material.

On this page you are provided with information, specifications and technical data about the Megasun Vertical Boilers provided by Solarnet S.A. Boiler Storage Tanks Manufacturer. “Megasun Boilers” are manufactured in a variety of types and can be also used as hot water storage tanks. They comply to DIN 4753 and EN 12897 specifications, are tested according to the international hygiene regulations and have a capacity ranging from 150 to 5000 liters.

Megasun hot water boilers are ideal for home use as well as for hotels, offices, mansions etc, are provided with single, double, triple power source with buffers and are available in 5 different colors. Their insulation of high density cast polyurethane is eco friendly and ensures hot water for longer. Furthermore, Megasun hot water boilers are the fastest on the market due to their large heat exchanger, making them also cost-effective.

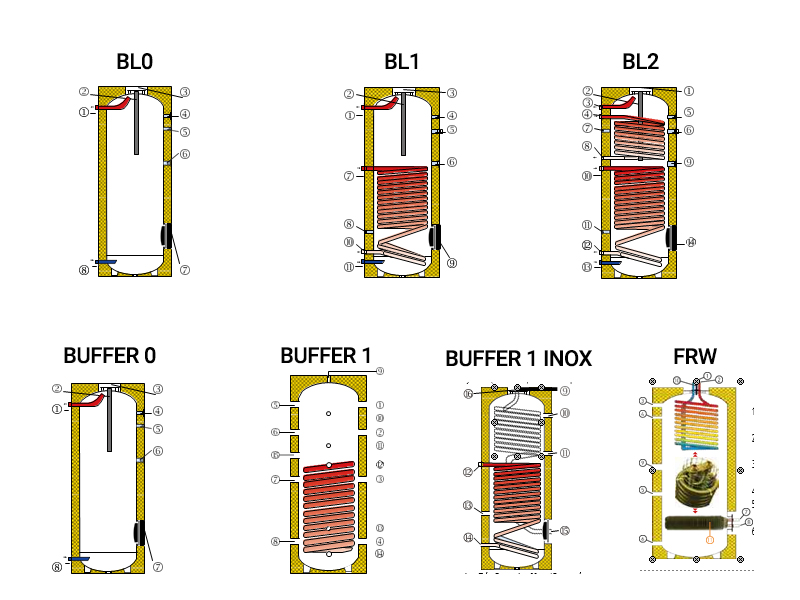

The types of vertical hot water boilers and storage tanks are the following:

Type BL0, without coils (150, 200, 300, 420, 500, 800 & 1000 litres)

Type BL1, with one coil heat exchanger (150, 200, 300, 420, 500, 800, 1000, 1500, 2000, 2500, 3000, 4000 and 5000 litres)

for connection to solar collectors

Type BL2, with two coil heat exchangers (150, 200, 300, 420, 500, 800, 1000, 1500, 2000, 2500, 3000, 4000 and 5000 litres)

for connection to solar collectors and central heating system

BUFFER-0, BUFFER-1, BUFFER-1 INOX (150, 200, 300, 420, 500, 800 & 1.000 litres)

for connection to solar water heaters and boiler

Type FRW1, (Fresh Water) 150L – 200L – 300L

Hot water tank for heat pump – solar water heaters.

General Characteristics of Megasun Hot Water Boilers:

Material: Steel plate USD37.2 quality

Welding: Robotically welded in inert gas environment

Cleaning: 6 point metal blasting

Internal protection: Glass enamel baked at 850° C

Function Pmax: 6 bar

Testing Pmax: 15 bar for 5 minutes

Function Tmax: +95° C

Insulation:

Material: Polyurethane CFC & FCKW Free

Density: 40 kg/m3

Thickness: 65 mm

(For storage tanks 800, 1000, insulation is made from flexible polyurethane 70 mm and is detachable for easier passage during installation)

Outer Cover Material: PVC in various colors

Heat Exchanger Type:Coil heat exchanger made of heavy duty steel tube 33mm (tubo).

Electrical Backup (upon request): 2 kw to 4 kw (220-240V, one-phase) with thermostat or 6 kw, 9 kw ή 12 kw (three-phase, 380V) without thermostat.

Description of BL0, BL1, BL2, BUFFER & FRW1 Storage Tanks

Tank weights when empty (in KG)

| Litres / Type | BL0 | BL1 | BL2  | Buffer 0 | Buffer 1 | Buffer 1 INOX | FRW1 |

| 150 | 51 | 64 | 69 | 49 | – | – | 49 |

| 200 | 66 | 82 | 90 | 60 | – | – | 64 |

| 300 | 94 | 108 | 128 | 90 | 118 | 129 | 96 |

| 420 | 118 | 146 | 156 | 108 | 132 | – | – |

| 500 | 122 | 165 | 182 | 117 | 150 | 162 | – |

| 800 | 137 | 176 | 210 | 127 | 168 | 180 | – |

| 1000 | 157 | 195 | 228 | 148 | 192 | 204 | – |

| 1500 | – | – | – | – | – | ||

| 2000 | – | – | – | – | – | ||

| 2500 | – | – | – | – | – | ||

| 3000 | – | – | – | – | – | ||

| 4000 | – | – | – | – | – | ||

| 5000 | – | – | – | – | – |

Thermal Insulation:

Polyurethane Foam CFC & FCKW free

Density: 40 kg/m3

Thickness: 65 mm

Thermal Conductivity: 0,023 W/mk

Fire Class: Β3, auto extinguishable

Hydraulic Connexions BL:

| Volume | 150 L | 200 L | 300 L | 420 L | 500 L | 800 L | 1000 L |

| Sensor | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ | 1/2″ |

| Heat exchangers | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ |

| Hot-Cold inlets | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ |

| Electric Element | 1½” | 1½” | 1½” | 1½” | 1½” | 1½” | 1½” |

| Recirculation | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ | 1″ |

Hydraulic Connections BL1:

| Volume | 1500 – 2000 – 2500 – 3000 – 4000 – 5000 L | ||||||

| 1 | Hot water outlet | 2″ | |||||

| 2 | Collector or Heater Inlet | 1 ¼” | |||||

| 3 | Recirculation connection | 1 ¼” | |||||

| 4 | Collector or Heater Outlet | 1 ¼” | |||||

| 5 | Cold Water Inlet | 2″ | |||||

| 6 | Discharge | 1 ¼” | |||||

| 7 | Cleaning Flange | Φ170 | |||||

| 8 | Electric Back-up inlet * | 3 Χ 1 ½” | |||||

| 9 | Position for Control Panel | ||||||

| 10 | Sensor inlet | 1/2″ | |||||

| 11 | Magnesium rod | ||||||

Hydraulic Connections BL2:

| Volume | 1500 – 2000 – 2500 – 3000 – 4000 – 5000 L | ||||||

| 1 | Hot Water Outlet | 2″ | |||||

| 2 | Heater Inlet | 1 ¼” | |||||

| 3 | Recirculation Connection | 1 ¼” | |||||

| 4 | Heater Outlet | 1 ¼” | |||||

| 5 | Collector Inlet | 1 ¼” | |||||

| 6 | Collector Outlet | 1 ¼” | |||||

| 7 | Cold Water Inlet | 2″ | |||||

| 8 | Discharge | 1 ¼” | |||||

| 9 | Cleaning Flange | Φ170 | |||||

| 10 | Electric Back-up inlet * | 3 Χ 1 ½” | |||||

| 11 | Position for Control Panel | ||||||

| 12 | Sensor Inlet | 1/2″ | |||||

| 13 | Magnesium rod | ||||||

| 14 | Sensor Inlet | 1/2″ | |||||

* For the Boilers of 2000 ltrs and over there is the posibility of installing of a third electric resistance too under the cleaning flange.

Hydraulic Connexions FRW1:

| Volume | 150 – 200 – 300 L |

| Position sensor DHW | 1/2″ |

| Location Solar sensor | 1/2″ |

| Supply flow – Return from heat pump | 1″ |

| Supply flow – Return from solar panel | 3/4″ |

| Cold water entrance | 3/4″ |

| Hot water outlet | 3/4″ |

| Electric resistancee | 1½” |

| Air ventilator | 1/2″ |

Corrosion Protection

Inner cleaning of the tank with automated sand blasting (notchemically) resulting in a perfect adherence of the enamel. Food grade enamel quality applied with a “double direct” method and baked at 850° C. Extra corrosion protection is offered by magnesium rods that must be checked and replaced if necessary every 6 months to 2 years, depending on the quality of the water.

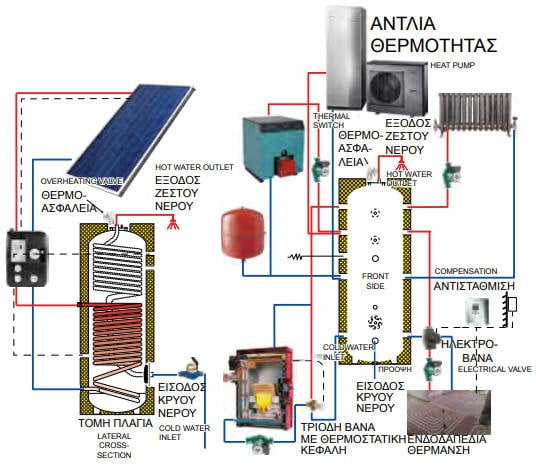

Backup Heating Source

If solar power is not sufficient to warm the water, a backupheating source can be used, either through an electric element or another heating source (central heating burner) that will be connected to the upper heat exchanger (BL2 models).Control of the electric element is made through the built in thermostat. It is recommended the thermostat be positioned between 50° C and 60° C during winter months and between 45° C and 50° C during summer.

Thermostat

Control: incorporated

Model of thermostat: B2-10

Protection at IP: 00

Tmax – maximum environmental temperature: 105 ºC

Cycles start / pause: 10.000 times (cycles)

Fire resistance category: B

Environmental function: Clean Εnvironment

Regulation: between 30° C – 80°C

Contacts: bakelite – silver

Protection cap from nylon 6 (flame retardant).

230 V /20 A

Backup Heating Source Using the Second, UpperHeat Exchanger

Coil type heat exchanger, from heavy duty steel (type Tubo) integrated in the upper part of the tank, in order for the secondary heating source to heat only the upper part of the tank. Further technical data concerning the upper heat exchanger refer to the table concerning BL2 tanks.

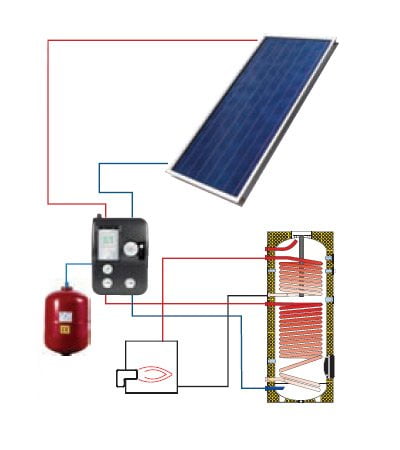

Used as a pump, regulator and air venting valve in solar heating systems. With the hydraulic kit, hydraulic balancing, flow measurement and venting can be performed directly in the station. The built-in SETTER Inline UN allows the required quantity of fluid in the primary circuit to be exactly and simply set and checked. The continuous venting system meets the most demanding requirements and keeps the system free of air.

Systems which are correctly balanced hydraulically and air-free guarantee optimal energy extraction, and are thus more cost-effective in the sense of the energy-saving directives laid down by law. Using the scale, which is pre-calibrated for glycol, the technician can set and check the exact flow-rate values on-site. Neither training courses nor expensive measuring devices are required. Installation and venting can be carried out by one person working unaided.

There are also optional peripheral accessories, such as thermostats and electric resistances which may be purchased separately upon request.

Download the pdf to view details about all peripheral accessories.

Global recognition

FIRST PRIZE OF EXCELLENCE FROM THE MINISTRY OF DEVELOPMENT