Solar water heaters with quality guarantee for 48 years

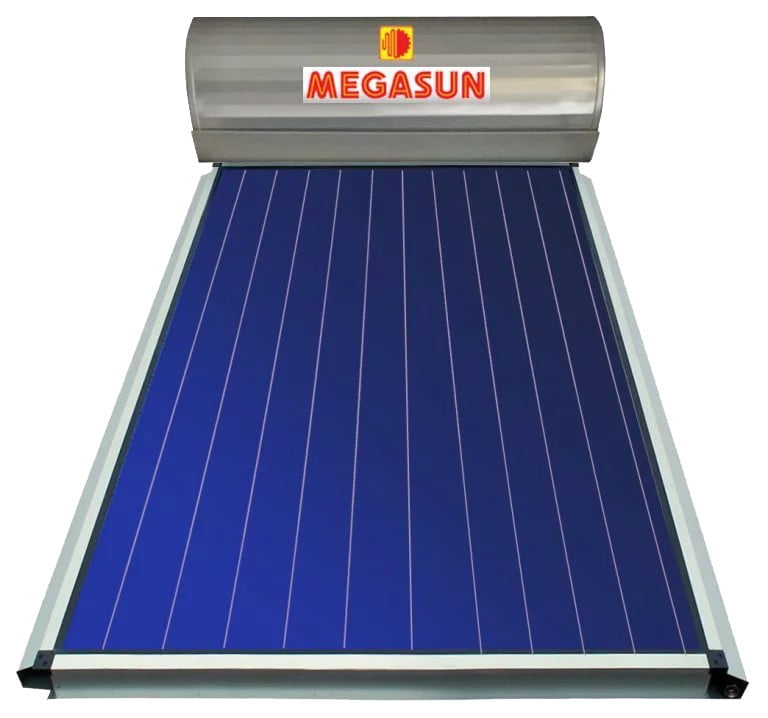

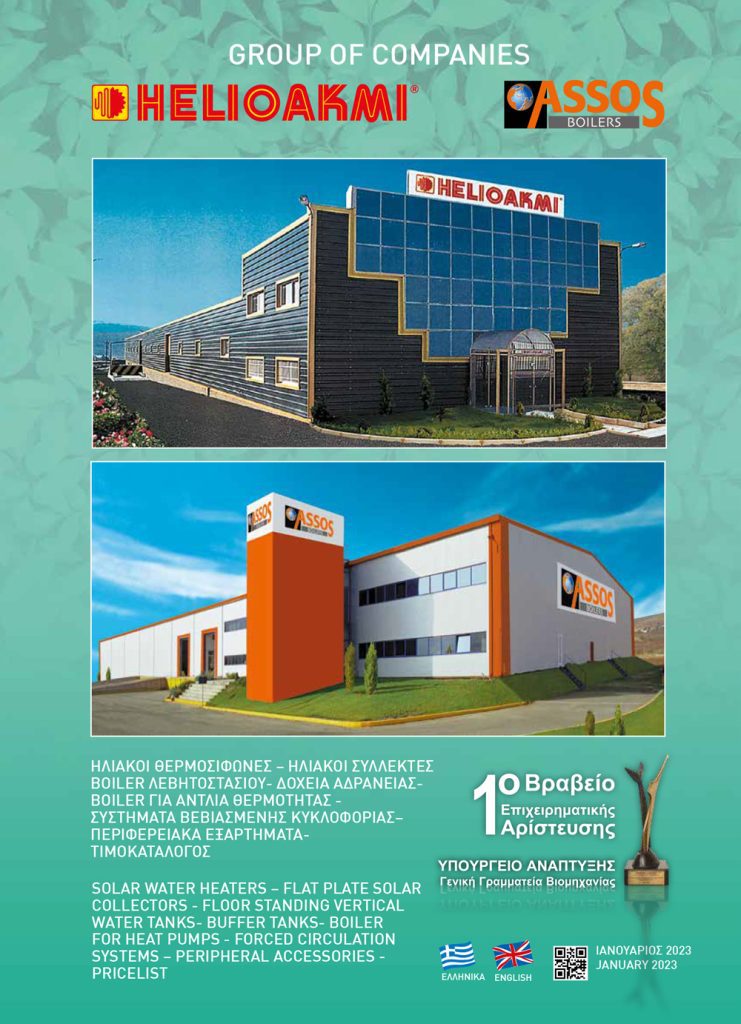

Helioakmi S.A. is a manufacturer of solar energy systems since 1976, specializing in forced circulation systems, as well as in solar panels and solar water heater products known worldwide as MEGASUN.

The high quality and international recognition of Helioakmi S.A. solar water heaters have brought us in a position among top solar water heater manufacturers. Indeed at Helioakmi we have been world leaders in solar water heaters 48 years before others discovered the power of the sun.

48 years of manufacturing solar panels and solar heaters means 48 years of innovating in the field and introducing new technologies.

Four decades of continuous development, combined with vast experience and extensive research have established MEGASUN products as leaders in most world markets.

Helioakmi Abroad

Internationally recognized in over 70 countries

Thousands of MEGASUN Solar Water Heaters by Helioakmi S.A. are successfully used in most countries of the world – from Athens to the U.S.A. and from Africa to Australia, to all of Asia and the Far East and Europe – provide continuous and abundant hot water.

Today HELIOAKMI MEGASUN not only represents highly specialized technology and the experience of 48 years, but high quality systems, meeting the highest demands.

Latest news

HAPPY CUSTOMERS

CERTIFICATIONS - AWARDS

DISTRIBUTORS WORLDWIDE

CERTIFICATIONS - AWARDS

HELIOAKMI products (MEGASUN) have been certified by the largest recognized Technology Institutes in the world, such as: Greece, European Union, Germany, France, Italy, Spain, Portugal, Netherlands, Switzerland, Czech Republic, Slovenia, Australia, Korea, Korea, etc.

FIRST PRIZE OF EXCELLENCE FROM THE MINISTRY OF DEVELOPMENT